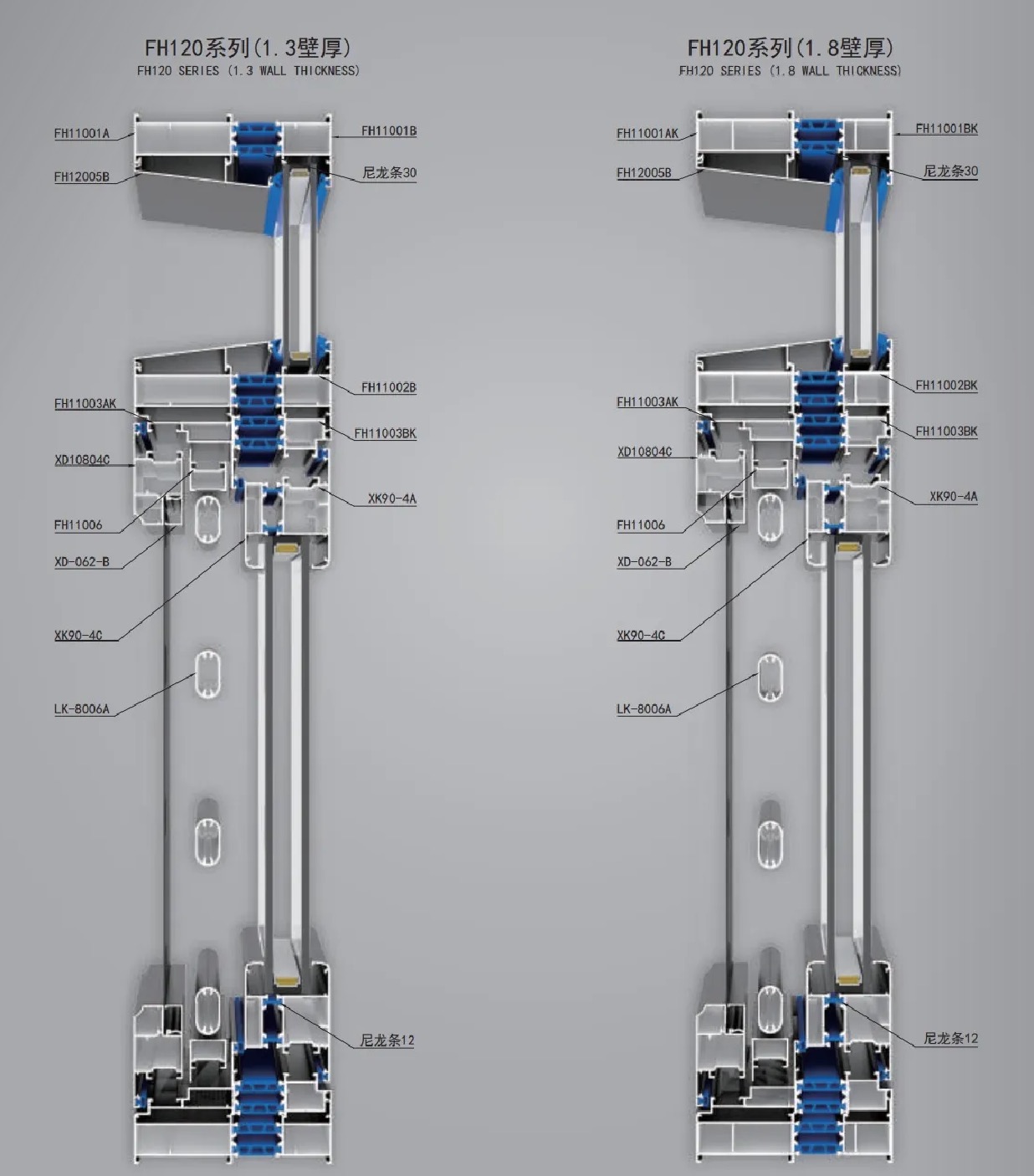

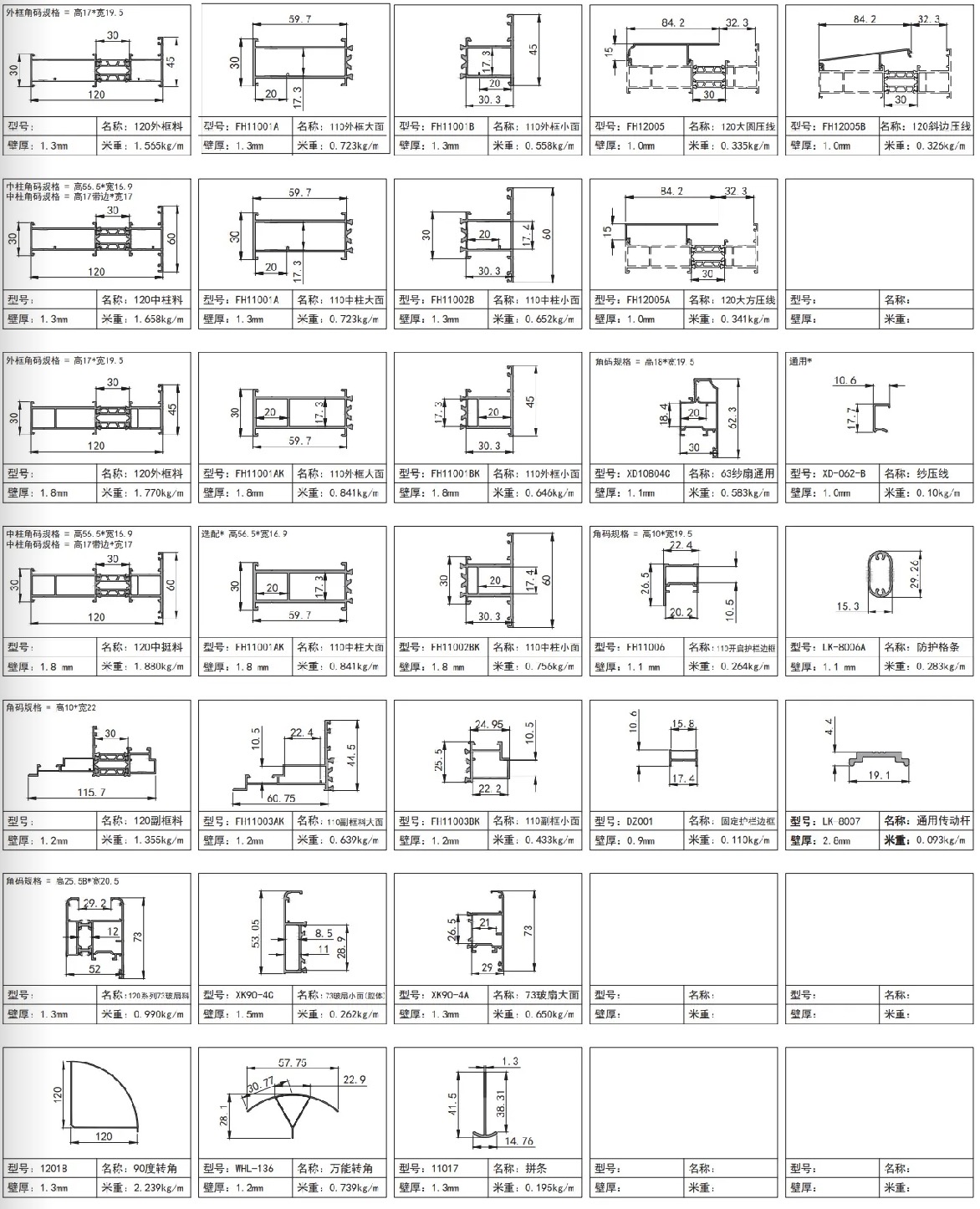

FH120 series energy-saving heat-insulated casement windows

Fluorocarbon spraying is a high-end spraying process that features excellent fade resistance, frost resistance, corrosion resistance to atmospheric oxygen pollution (such as acid rain), strong ultraviolet resistance, and strong crack resistance, allowing it to withstand harsh weather conditions, far surpassing general coatings.

Decontamination - water washing - alkali washing - water washing - acid washing - chrome washing - water washing - pure water washing - primer coating - topcoat coating - gloss coating - curing treatment - quality inspection to meet the standards of the American Architectural Manufacturers Association AAMA-605.02.90.

The stability and durability of fluorocarbon coatings are 30% to 80% higher than those of general coatings, with a service life of up to 50 years under normal climatic conditions.

The surface of aluminum profiles must undergo a series of chemical treatments to enhance aesthetics and improve the adhesion between the metal surface and the paint layer, as well as its anti-oxidation capability.

Profiles are baked three times at optimal humidity and time to enhance their adhesion and wear resistance (hardness).

Due to its excellent characteristics, it is increasingly favored by the high-end market worldwide.

Interior colors: gray, high-gloss white, metallic gray, metallic coffee, snowflake gray, black gold, fluorocarbon gray, fluorocarbon gold, white oak, Norwegian forest.

Exterior colors: gray, brown, metallic gray.

Our FH120 Series Energy-Efficient Thermal Insulation Casement Windows are manufactured using advanced technology to ensure superior performance in energy efficiency and thermal insulation. Ideal for modern homes and commercial buildings, our windows meet international standards.Contact us today for more information and a customized quote.