Machining

Machining is a technical process that makes parts, tools, and instruments by removing materials. This process typically involves the use of a variety of machine tools, such as milling machines, lathes, and drilling machines, to transform raw materials into the desired shape and size through precise cutting and forming operations. Although machining is primarily applied to metals, it is equally applicable to other materials such as wood, ceramics, and plastics. Machining shops may also use 3D printers for additive manufacturing to complement traditional subtractive manufacturing techniques.

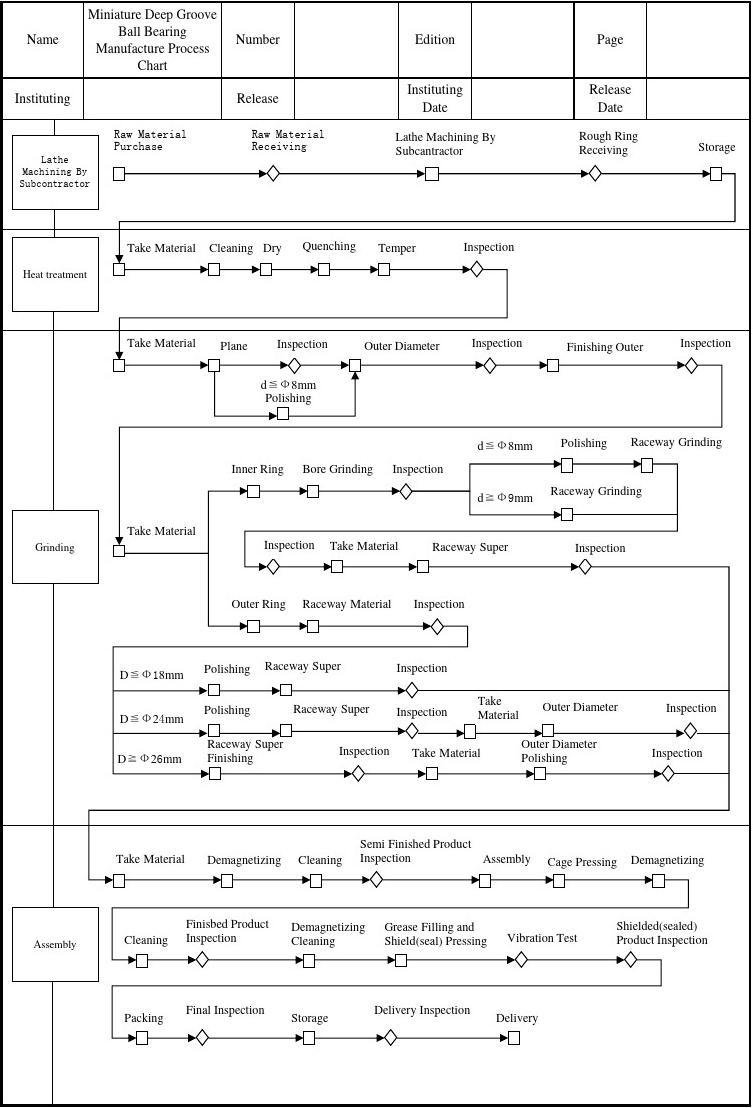

The machining process includes design, CAD analysis, transmission, programming, process analysis, equipment reorganization, processing, inspection and maintenance. Among them, the design and process analysis are very important, and the accuracy of these two links determines the quality of machined parts. Designers need to develop accurate drawings of parts, including specific dimensions and requirements. Process analysis requires the analysis of the processing plan and the making of a reasonable process plan.

Machining is suitable for large-scale, complex structure, multi-material processing parts, molds, models, etc., according to the different quantities of products and product structure, you can choose the corresponding process, provide the corresponding product solutions.

01. Processing equipment

1). Ordinary lathes:

Lathes are mainly used to process shafts, discs, sleeves and other workpieces with rotating surfaces, and are the most widely used type of machine tools in machinery manufacturing. (Accuracy 0.01mm can be realized)

2). Ordinary milling machine:

It can process planes, grooves, various curved surfaces, gears, etc., and can also process more complex profiles. (Accuracy 0.05mm is possible)

3). Grinder

A grinding machine is a machine tool that grinds the surface of a workpiece. (Accuracy of 0.005mm, small parts of 0.002mm)

4). CNC lathes

It mainly processes batch products, high-precision parts, etc. (Accuracy 0.01mm can be realized)

5). CNC milling machine

It mainly processes batch products, high-precision parts, complex parts, large workpieces, etc. (Accuracy 0.01mm can be realized)

6). Wire cutting

The electrode used for slow wire is brass wire, and the medium wire is used for molybdenum wire. The slow wire processing precision is high and the surface finish is good. Processing some fine holes, fine grooves, etc. (The accuracy of slow wire can be 0.003mm, and the accuracy of medium wire can be 0.02mm)

7). Spark machine

EDM can process materials and workpieces with complex shapes that are difficult to cut by ordinary cutting methods, and are not affected by the hardness of the material or the heat treatment conditions. (Accuracy 0.005mm is possible)

Our Machined Parts are manufactured using advanced CNC machining techniques to ensure superior precision, durability, and performance. Ideal for automotive, aerospace, and heavy machinery applications, our machined parts are available in various materials, including aluminum, steel, and titanium.Contact us today for more information and a customized quote.