Foundry Goods

Castings are metal forming objects obtained by various casting methods, that is, the smelted liquid metal is injected into the pre-prepared casting mold by pouring, injection, suction or other casting methods, and after cooling, it is polished and other subsequent processing methods to obtain an object with a certain shape, size and performance.

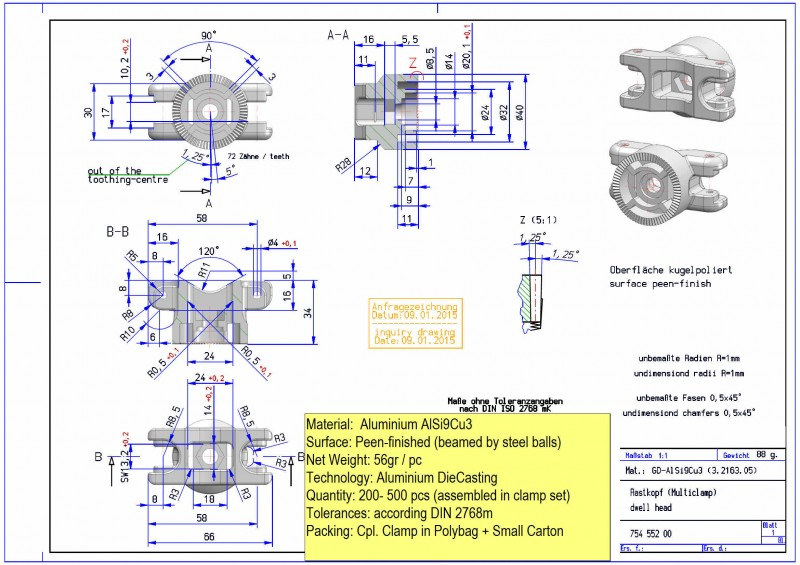

There are many classification methods for castings: according to the different metal materials used, they are divided into steel castings, iron castings, copper castings, aluminum castings, magnesium castings, zinc castings, titanium castings, etc. Each type of casting can be further divided into different types according to its chemical composition or metallographic structure. For example, iron castings can be divided into gray iron castings, ductile iron castings, compacted graphite iron castings, malleable iron castings, alloy iron castings, etc.; According to the different casting molding methods, castings can be divided into ordinary sand castings, metal castings, die castings, centrifugal castings, continuous castings, investment castings, ceramic castings, electroslag remelting castings, bimetal castings, etc. Among them, ordinary sand castings are the most widely used, accounting for about 80% of the total casting output. Non-ferrous metal castings such as aluminum, magnesium, and zinc are mostly die castings.

Our Castings are specifically designed for use in automotive, aerospace, and heavy machinery industries. With high strength, excellent durability, and precise dimensional accuracy, they provide a reliable and cost-effective solution for demanding industrial applications. Contact us today for more information and a customized quote.